|

||

|

|

|

|

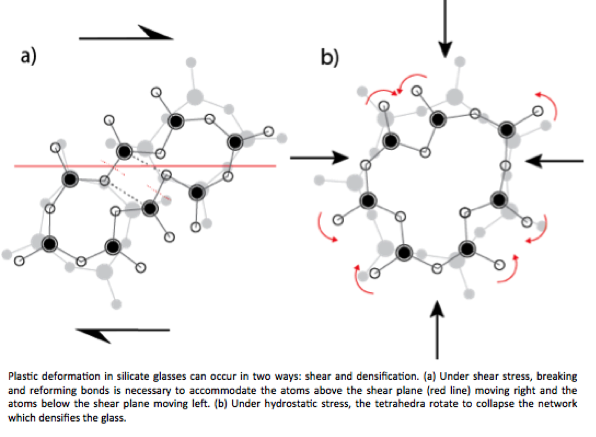

Home People Research Thin films Bio-inspired minerals Oxide glasses Nanostructured metals Nanostructured ceramics Group News Publications Facilities Available Positions Alumni | Oxide glasses Silicate glasses are very important in applications that include touchscreen and other electronic displays, vehicle windows, medical equipment, and many others. In many applications (e.g. cell phones) surface wear and durability are important issues. Current projects include: Current students include: Nicole Wiles, Zach Rouse, Lauren Morehouse, and Lauren Kilcullen Plastic deformation mechanisms in silicate glasses Our hypothesis is that the plastic deformation mode determines the stress state and the stress state determines when fracture occurs, thus plastic deformation controls fracture and surface damage.

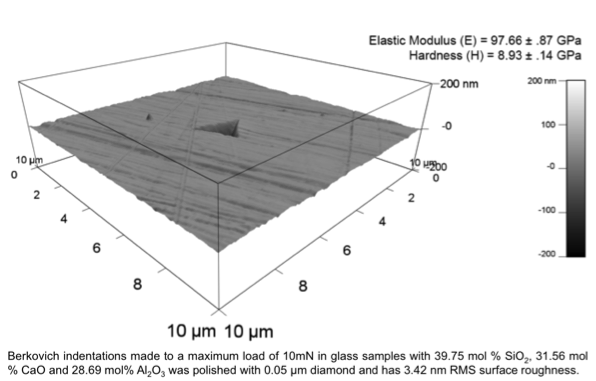

Hardness and indentation modulus of calcium-aluminosilicate, magnesium-aluminosilicate, and calcium-galliosilicate glasses

This non-monotonic behavior is unexpected since hardness is often said to scale with modulus. We determined the speciation in the glass using NMR and applied topological constraint theory, a model in which the average number of bonding constraints per atom is said to determine the hardness, in an attempt to understand the observed behavior, but found an inverse correlation. Modifications to the constraint model provide a significant improvement, but do not describe the non-monotonic behavior. Instead we suggest that the variations in hardness arise from a transition from shear to densification-dominated behavior, which is determined by the species present. We have varied the species present by replacing Ca with Mg to create magnesium-aluminosilicate (MAS) glasses, and Al with Ga to create calcium-galliosilicate (CGS) glasses. CAS, MAS, and CGS glasses all show similar behavior, but at different stress levels and with different compositions at the hardness minimum according to the species present. We are currently studying the effects of composition variations perpendicular to the tectosilicate line, effects of hydrostatic densification, and mixed modifier effects. Understanding how local structure and composition controls plastic deformation is essential to understanding not only hardness but durability of glass surfaces. |

|

|

||

|

||

| Last Update: 2016/12/22 | JDC | <-- Click these initials to email the webmaster with comments / suggestions | |