|

||

|

|

|

|

Home People Research Thin films Bio-inspired minerals Oxide glasses Nanostructured metals Nanostructured ceramics Group News Publications Facilities Available Positions Alumni | Thin films Thin films are used in many different applications, from microelectronics to optics to wear- and corrosion-resistant coatings. Thin films often support extremely high stresses due both to the constraints of the substrates to which they are attached, and to unique microstructural and dimensional constraints that limit deformation. Current projects include:

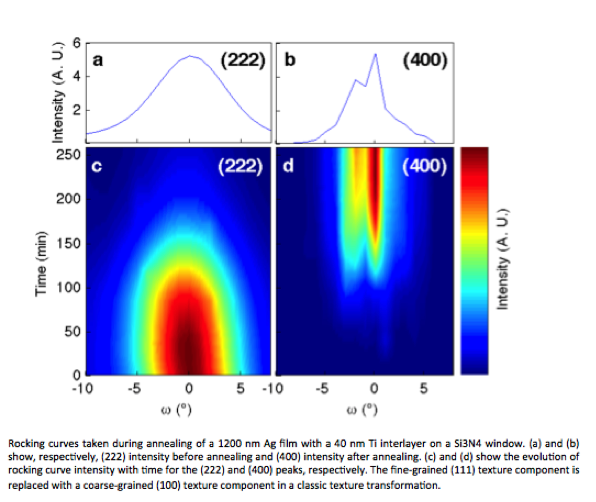

Texture transformations in FCC thin metal films We have studied this phenomenon in some detail and have shown that the prevailing model, which explains the transformation in terms of a minimization of strain and interface energy, is not correct. For example, we conducted experiments in which we applied stresses to films via a bulge test while annealing in situ and observing the texture transformation using synchrotron radiation.

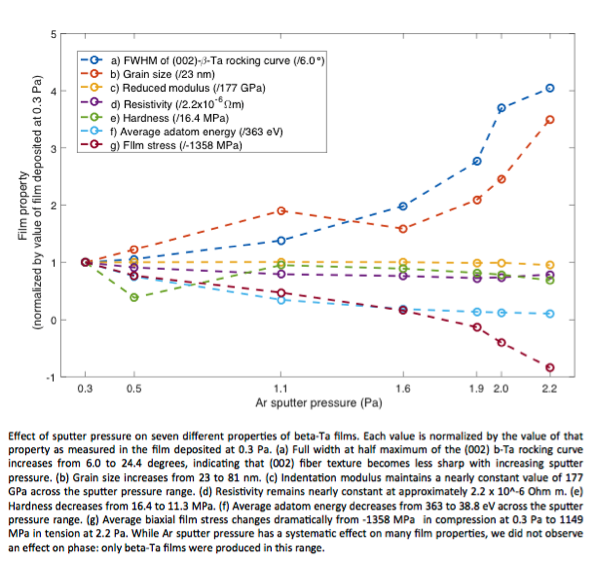

We showed that films transform even when the stresses are too low to drive the transformation and even when the transformation causes the strain energy to increase. We have also shown that the transformation (although not the structure) is insensitive to interface conditions. References Baker, S.P., B. Hoffman, L. Timian, A. Silvernail, and E.A. Ellis, Texture Transformations in Ag Thin Films. Acta Materialia, 2013. 61(19): p. 7121-7132. Baker, S.P., K. Saha, and J.B. Shu, Effect of thickness and Ti interlayers on stresses and texture transformations in thin Ag films during thermal cycling. Applied Physics Letters, 2013. 103: p. 191905. Beta phase formation in thin Ta films The US consumes about $300 million of tantalum each year, with the majority used to make tantalum capacitors--for which the α-Ta phase is used--for use in microelectronic devices such as cell phones, laptops, and automotive electronics. Recently, the discovery of giant spin hall effect (GSHE) in β-Ta films has ignited new interest in this phase. Clearly, understanding the conditions that determine which phase forms as well as the stability of the β phase are extremely important. Yet, despite 50 years of research, the phase selection mechanism is unknown. One of the main reasons this problem has not yet been solved is that many different variables have been varied (or left uncontrolled) in previous work. We have studied the effect of Ar sputter gas pressure, pAr, on phase formation while holding all other variables (substrate, sputter power, base pressure, etc.) constant with a particular focus on minimizing impurities. Unlike previous work, we find that 100% β phase is formed over the entire range 2 ≤ pAr ≤ 16 mTorr. In addition, we find that the texture, stresses, grain size, and hardness vary systematically with pAr and are consistent with changes in the mean free path for the motion of Ta atoms during deposition.

|

|

|

||

|

||

| Last Update: 2016/12/22 | JDC | <-- Click these initials to email the webmaster with comments / suggestions | |