|

|

|

|

|

Home People Research Thin films Bio-inspired minerals Oxide glasses Nanostructured metals Nanostructured ceramics Group News Publications Facilities Available Positions Alumni | Nanostructured metals

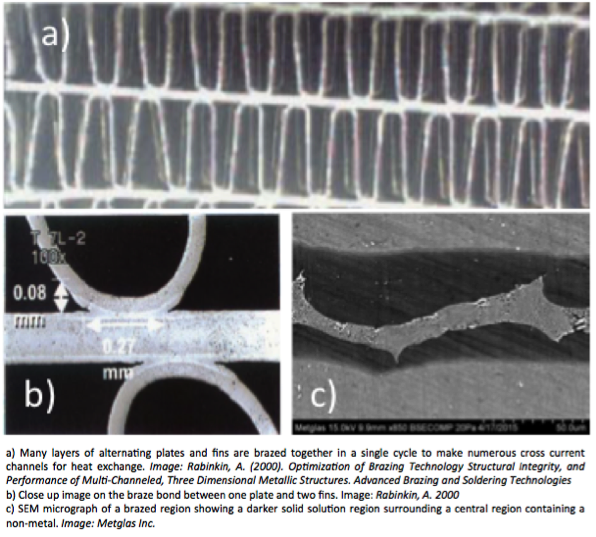

Because of their high strength and forgiving failure characteristics, metals remain the premier class of materials for structural applications, and no other material competes for electrical conductivity, optical reflectivity, and ease of fabrication. Innovation continues at a rapid and accelerating pace in many areas of metallurgy. Current projects include: One of the most effective ways to create complex lightweight metallic parts is by brazing together intricate stacks of (relatively) inexpensive parts made from stamped metal sheets. Heat exchangers for use in a variety of applications, including automotive, are just one example. These devices are critical for reducing pollution and conserving energy. but operate at high temperatures in corrosive environments. We are working to understand the strength of brazed joints made using metallic glass brazing foils (MGBF). To form a joint, a thin sheet of amorphous metal (the MGBF) is placed between the parts to be joined, the parts are pressed together and heated to melt the MGBF and form the brazed joint. Use of MGBF facilitates manufacturing compared with more traditional pastes since the thin foils can be cut and stamped to match the parts to be joined. We conducted lap shear tests of Ni-based MGBF's to determine their mechanical properties and investigated the composition, structure, and nanohardness of the constituents in the braze zone at the submicrometer scale. An alloy (MBF67) with higher Cr content and phosphorous as a glass former, showed better corrosion resistance, but lower strength that an alloy (MBF 51) with lower Cr content and boron as a glass former. Differences in strength can be attributed to the microstructure and properties within the joint, but the overlap in the lap shear stress plays an even more important role.

|

|

|

|

|

| Last Update: 2016/12/22 | JDC | <-- Click these initials to email the webmaster with comments / suggestions |